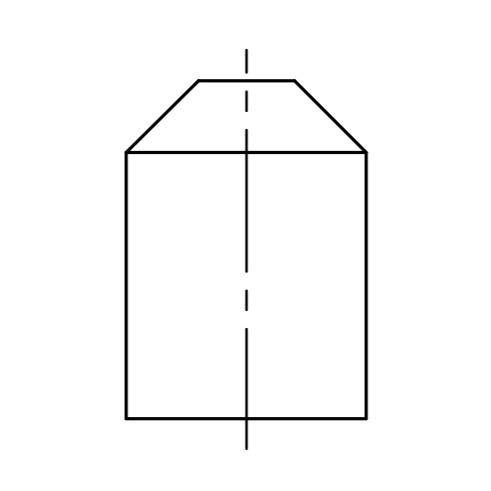

| A |

|

The A nose or Pointed face tip is a general purpose weld face suitable for most spot welding applications. |

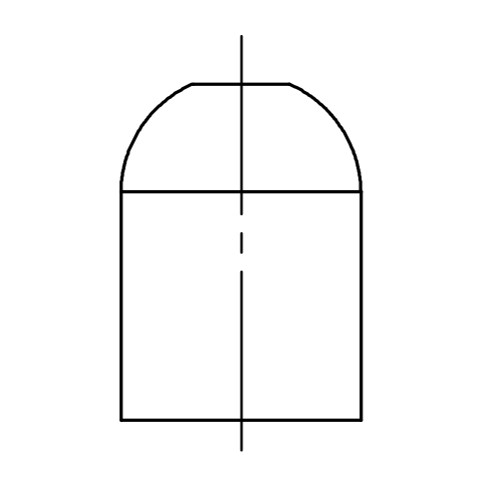

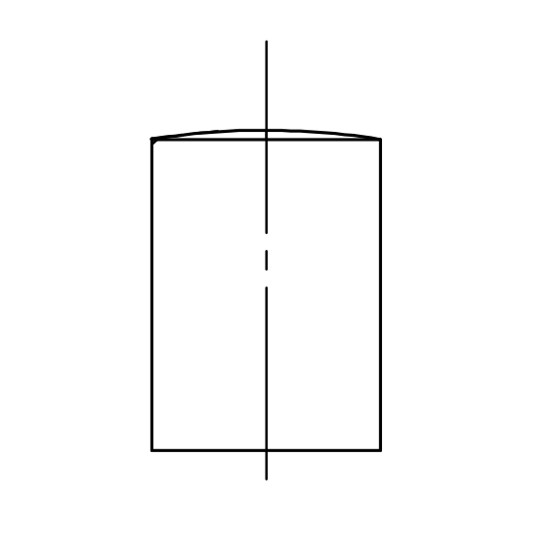

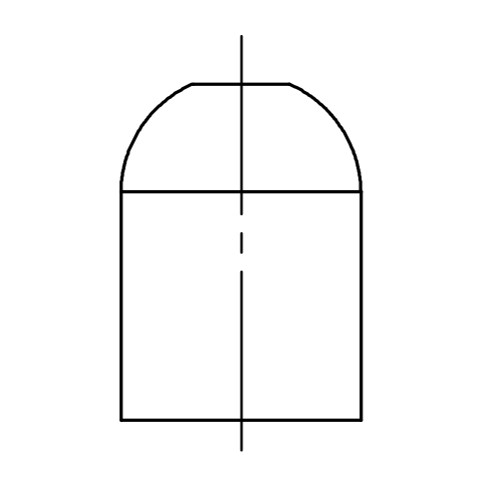

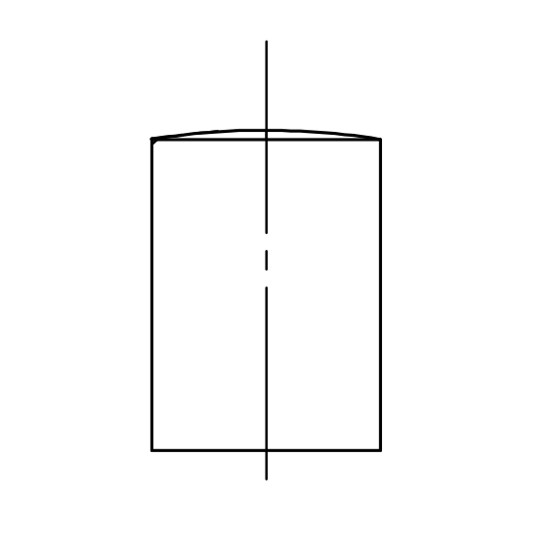

| B |

|

The B nose or Dome face tip is the most commonly used weldface because the design accommodates modest misalignment problems as contact can still be made on the radius during welding. |

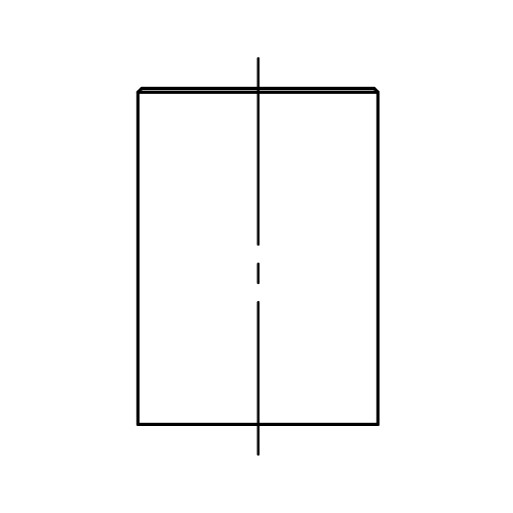

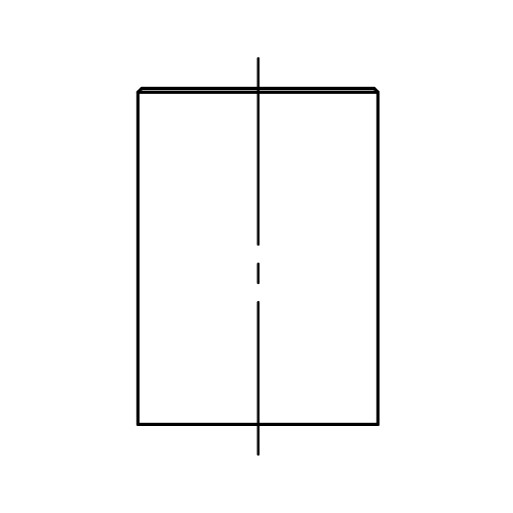

| C |

|

The C nose of Flat face tip is frequently used as a backup electrode for projection welding, cosmetic welds, or to control heat balancing of the weld by controlling the current density. |

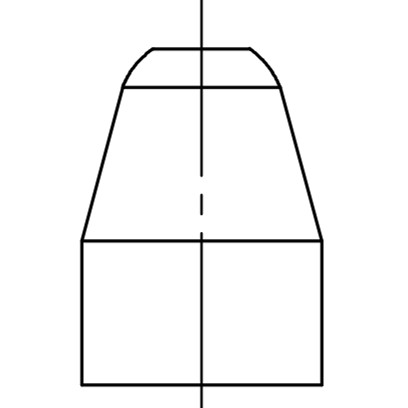

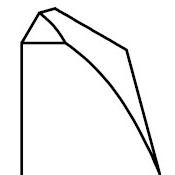

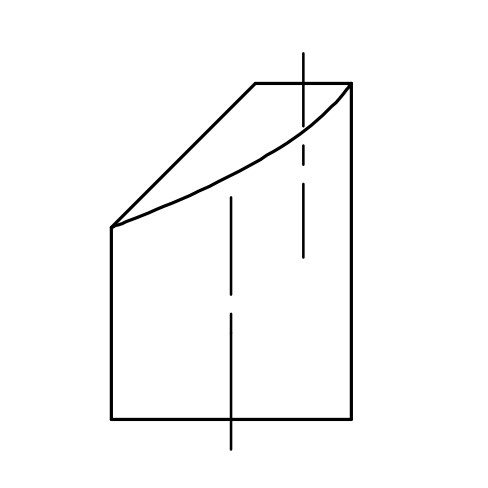

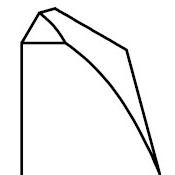

| D |

|

The D nose or Offset face tip is used for welds in tight spaces typically on a flange or tight corner. It requires manual orientation during setup. |

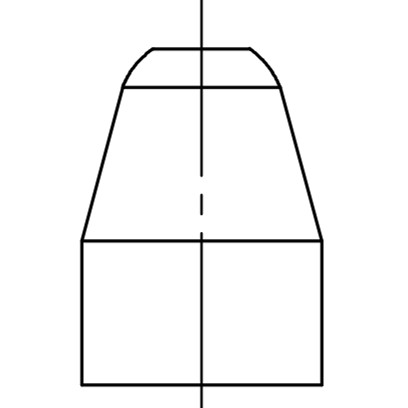

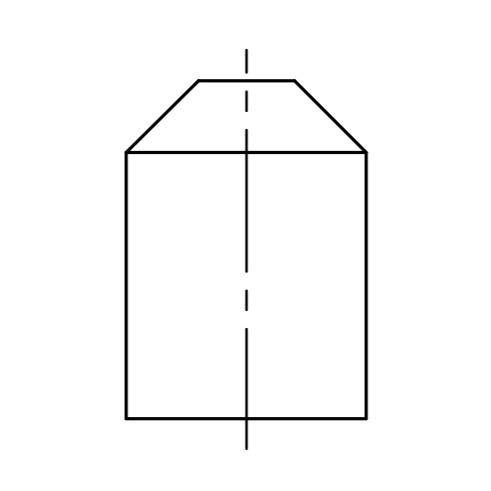

| E |

|

The E nose or Truncated face tip is an efficient design that does not trap weld flash on the face and may reduce mushrooming. |

| F |

|

The F nose or Radius face tip is typically used for aluminum welding because it provides point contact to break through the aluminum oxide layer on the surface while still providing an adequate weldface to manage the current density during welding. |

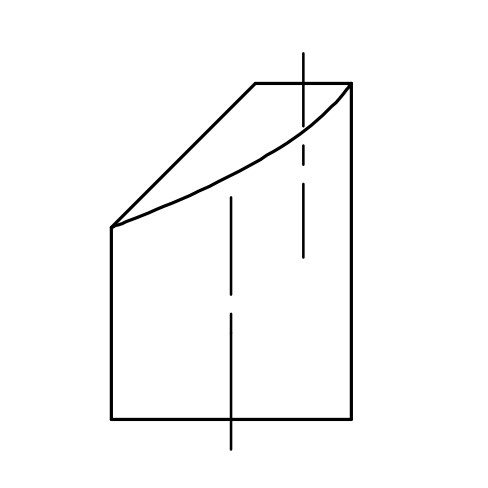

| H |

|

The H nose or angled offset nose is designed to accommodate the angled offset of the electrode holder and ensure the weldface is perpendicular to the workpieces. |

| G |

|

The GCAP nose is designed for welding galvanized steels. The revolutionary design provides no sticking on the first weld and the shape minimized brass build up on the weld face. The GCAP is available in a straight, 30 degree angle engagement, or an offset design. |